In an era driven by data and technology, industries across the spectrum are constantly seeking innovative solutions to enhance efficiency, reduce costs, and improve overall operations. One such solution that has been making waves in various sectors is the integration of custom RFID (Radio-Frequency Identification) tags with specialized software systems. While RFID technology has been widely adopted in applications such as inventory management and access control, its potential in laundry management, particularly when it comes to gas cylinders, remains an untapped resource.

This article explores the possibilities and advantages of integrating fashion custom RFID gas cylinder tags with laundry management software. We will delve into the transformative impact this integration can have on tracking, managing, and optimizing the use of gas cylinders in various industries.

The RFID Revolution: A Brief Overview

Before we delve into the specifics of custom RFID gas cylinder tags, let’s take a moment to understand the fundamental concept of RFID technology. RFID is a wireless communication technology that utilizes radio waves to identify and track objects. It consists of two main components: RFID tags (or transponders) and RFID readers.

RFID tags are small, electronic devices that store data and transmit it wirelessly to RFID readers when in proximity. These tags can be passive, meaning they rely on the energy from the RFID reader to transmit data, or active, which have their own power source and can transmit data over longer distances.

RFID technology has been embraced across various industries for its ability to provide real-time visibility, enhance security, and streamline operations. In laundry management, RFID has traditionally been used for tracking textile items, such as linens and uniforms. However, its application to gas cylinder management is a relatively uncharted territory that holds immense potential.

Custom RFID Gas Cylinder Tags: Tailored for Efficiency

Gas cylinders are integral components in a multitude of industries, including healthcare, manufacturing, hospitality, and laboratories. They are used for a wide range of purposes, from medical gases in hospitals to industrial gases in manufacturing plants. Efficient management of gas cylinders is essential to ensure a continuous and safe supply of gases while minimizing operational costs.

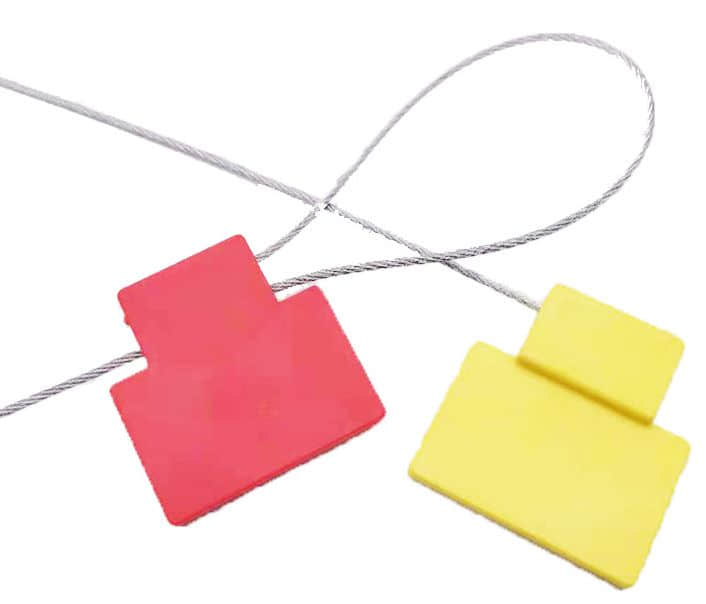

Custom RFID gas cylinder tags are designed to address the unique challenges associated with gas cylinder management. These tags are equipped with specific features that make them ideal for this application:

- Durability: Custom RFID gas cylinder Labels are built to withstand the harsh environments often encountered in industries where gas cylinders are used. They are resistant to chemicals, extreme temperatures, and physical wear and tear.

- Tamper-Evident: Many custom RFID gas cylinder Labels come with tamper-evident features, ensuring that any unauthorized access or interference with the gas cylinder is immediately detected.

- Long Read Range: To accommodate the often large and bulky nature of gas cylinders, these RFID tags have a longer read range, allowing for efficient data collection even from a distance.

- Data Capacity: Custom RFID gas cylinder Labels have ample data capacity to store essential information about the gas cylinder, including its contents, expiration date, and maintenance history.

- Battery-Powered: Depending on the specific requirements, some custom RFID gas cylinder tags are battery-powered (active tags), which enables continuous tracking and monitoring of the cylinder’s status.

Integration with Laundry Management Software: The Power of Data

Now, let’s explore how integrating custom RFID gas cylinder tags with laundry management software can revolutionize the way gas cylinders are tracked and managed.

1. Real-Time Visibility

One of the primary advantages of RFID technology is real-time visibility. When custom RFID gas cylinder tags are integrated with laundry management software, businesses gain instant access to the whereabouts and status of each gas cylinder. This visibility allows for more accurate tracking, reduced instances of misplaced cylinders, and efficient scheduling for cylinder replacements or refills.

2. Inventory Management:

Laundry management software equipped with RFID integration can provide detailed inventory management capabilities for gas cylinders. Businesses can easily monitor cylinder stock levels, track consumption rates, and set automatic reorder points. This proactive approach ensures a continuous gas supply, minimizing disruptions in operations.

3. Maintenance and Compliance:

Custom RFID gas cylinder tags can store maintenance and compliance data, including inspection dates, safety certifications, and expiration dates. When integrated with laundry management software, this information becomes readily accessible. As a result, businesses can proactively schedule maintenance and ensure that cylinders are compliant with safety regulations.

4. Usage Tracking:

Integrating RFID technology with laundry management software enables precise usage tracking. Businesses can monitor which departments or individuals are using gas cylinders, allowing for accurate cost allocation and accountability.

5. Enhanced Security:

Custom RFID gas cylinder tags equipped with tamper-evident features enhance security. Any unauthorized access or interference triggers immediate alerts in the laundry management software, allowing for swift action to be taken.

6. Analytics and Reporting

Laundry management software can generate detailed analytics and reports based on RFID data. These reports can provide insights into gas cylinder utilization, trends, and areas for potential cost savings or operational improvements.

Overcoming Challenges and Implementing RFID Solutions

While the potential benefits of integrating custom RFID gas cylinder tags with laundry management software are substantial, it’s important to address some of the challenges and considerations that organizations may encounter during implementation.

1. Initial Investment:

Implementing an RFID solution, including custom tags and software integration, involves an initial investment. Organizations need to assess their budget and evaluate the long-term ROI (Return on Investment) of such a system.

2. Compatibility:

Ensure that the chosen custom RFID gas cylinder tags are compatible with your existing gas cylinder infrastructure and laundry management software. Compatibility issues can lead to complications during implementation.

3. Data Security:

As RFID technology relies on wireless communication, data security is paramount. Organizations must implement robust security measures to protect RFID data from unauthorized access or tampering.

4. Training:

Proper training for staff members who will be using the RFID system is crucial. They need to understand how to operate RFID readers, interpret data, and respond to alerts or notifications.

5. Scalability:

Consider the scalability of the RFID solution. Will it accommodate future growth and evolving needs? Choose a system that can be easily expanded or adapted to meet changing requirements.

6. Compliance:

Depending on the industry, there may be specific regulations and compliance standards related to gas cylinder management. Ensure that the RFID system and tags meet these requirements.

7. Maintenance:

Like any technology, RFID systems require regular maintenance to ensure optimal performance. Organizations should have maintenance procedures and schedules in place.

8. Data Backup:

Implement a robust data backup and recovery plan to prevent data loss in case of system failures or unexpected events.

Case Study: Healthcare Industry

To illustrate the impact of integrating custom RFID gas cylinder tags with laundry management software, let’s consider a case study in the healthcare industry. Hospitals rely heavily on medical gases, such as oxygen and nitrous oxide, for patient care. Efficient management of gas cylinders is critical to ensure a continuous supply of these life-saving gases.

By implementing custom RFID gas cylinder tags and integrating them with laundry management software, a hospital can achieve the following benefits:

- Real-time visibility into the location and status of each gas cylinder, reducing the risk of running out of critical gases during emergencies.

- Automated alerts for cylinder maintenance, ensuring that cylinders are always in compliance with safety regulations.

- Usage tracking to allocate costs accurately to different departments and monitor cylinder consumption patterns.

- Enhanced security through tamper-evident features, preventing unauthorized access to gas cylinders.

- Detailed analytics and reports for optimizing gas cylinder utilization and budget allocation.

Conclusion: Maximizing Efficiency and Safety

The integration of custom RFID gas cylinder tags with laundry management software represents a significant leap forward in the efficient and safe management of gas cylinders across industries. Whether in healthcare, manufacturing, hospitality, or laboratories, businesses can benefit from real-time visibility, enhanced security, precise inventory management, and data-driven insights.

As technology continues to advance, the synergy between RFID technology and laundry management software opens up new possibilities for streamlining operations, reducing costs, and ensuring the uninterrupted supply of essential gases. It’s a paradigm shift that holds the promise of a safer, more efficient future for gas cylinder management.