Introduction

In today’s industrial landscape, the management of gas cylinders is a critical aspect of safety, efficiency, and cost control. Newest Custom RFID gas cylinder tags have emerged as a powerful tool to address these needs. Their adaptability and customization options make them invaluable for various industries and applications. This article delves into the world of custom RFID gas cylinder tags, exploring how they can be tailored to meet the unique needs of different businesses and applications.

Understanding Custom RFID Gas Cylinder Tags

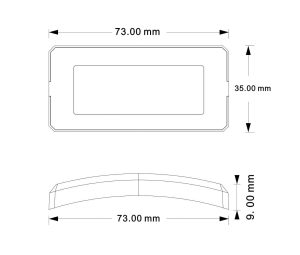

Custom RFID gas cylinder tags are small, durable devices that use Radio Frequency Identification (RFID) technology to store and transmit data about gas cylinders. This data can include cylinder identification numbers, gas types, inspection dates, and more. What sets custom RFID tags apart is their flexibility in design and functionality, making them highly adaptable to diverse requirements.

Customization Options

- Data Storage: The amount of data that custom RFID gas cylinder tagscan store varies. Customization allows businesses to choose the right tag with the appropriate data storage capacity based on their needs. For some, a simple tag with basic information suffices, while others may require more comprehensive data storage capabilities.

- Read Range: Different applications may require RFID tags with varying read ranges. For instance, in a manufacturing facility, shorter read ranges may be preferred for precise tracking, while in larger storage yards, longer read ranges may be necessary for efficiency. Customization allows businesses to select the optimal read range.

- Frequency: RFID tags operate at different frequencies, including Low-Frequency (LF), High-Frequency (HF), and Ultra-High Frequency (UHF). The choice of frequency depends on factors like the environment, the distance between the reader and the tag, and interference. Custom RFID tags can be designed to operate at the most suitable frequency for specific applications.

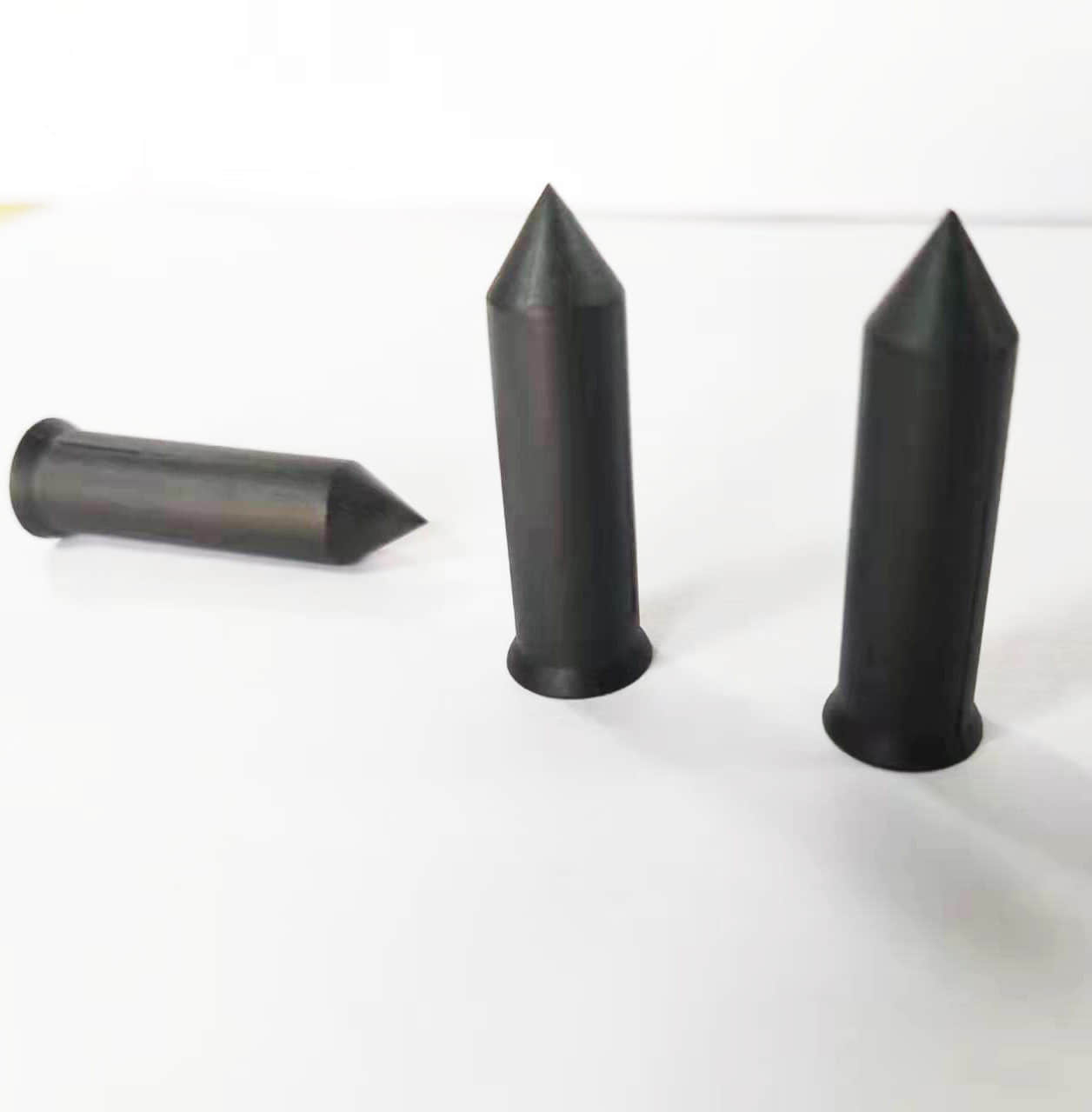

- Materials and Durability: Gas cylinders are often subject to harsh environments, including exposure to chemicals, extreme temperatures, and physical wear. Custom RFID gas cylinder tags can be manufactured with materials that ensure durability and resilience under such conditions. Options range from rugged plastic to metal-encased tags.

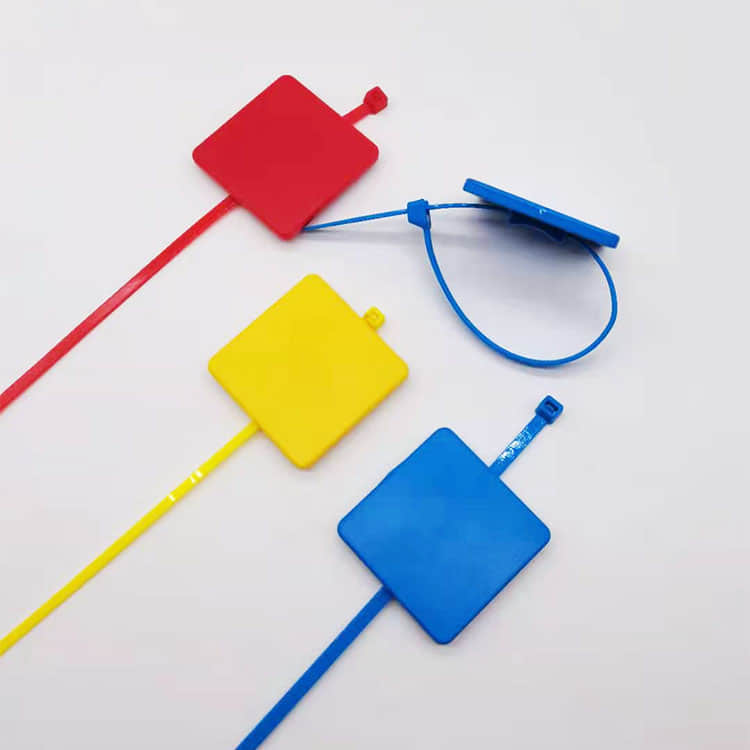

- Attachment Methods: The method of attaching RFID tags to gas cylinders can also be customized. Adhesives, cable ties, clips, or even embedded tags are among the attachment options available. These can be chosen based on the type of gas cylinder and how it is handled.

- Printing and Branding: Customization extends to the visual aspect of the tags. Businesses can opt to print logos, barcodes, QR codes, or any other branding elements on the tags. This not only aids in identification but also reinforces branding efforts.

Meeting Industry-Specific Needs

- Healthcare: Healthcare facilities often require RFID gas cylinder tags that can withstand sterilization processes. Customization can include tags designed to resist the harsh chemicals and high temperatures of autoclaves.

- Manufacturing: In manufacturing, where efficiency and precision are paramount, Custom RFID gas cylinder tags can be tailored to provide real-time data on cylinder usage, maintenance schedules, and inventory levels, optimizing production processes.

- Chemical Industry: In environments where gas cylinders store hazardous chemicals, custom tags may include safety alerts and emergency response instructions to enhance workplace safety.

- Hospitality: In the hospitality sector, RFID tags can be designed to integrate with inventory management systems, ensuring timely replacements and minimizing downtime for gas-dependent amenities like swimming pools or restaurants.

- Construction: For construction sites, RFID gas cylinder tags can be customized for ruggedness and ease of attachment, ensuring they remain securely affixed to cylinders amidst the demands of a construction environment.

Custom RFID gas cylinder tags represent a testament to the evolving landscape of technology-driven solutions in industrial settings. Their ability to adapt to various applications and industries demonstrates their versatility and value. As we continue to explore the customization possibilities for RFID gas cylinder tags, it’s important to highlight some additional considerations:

- Integration with Software: Custom RFID gas cylinder tags can be integrated with existing software systems. This allows for seamless data transfer, enabling businesses to monitor and manage their gas cylinders more effectively. It also facilitates automation in tasks such as inventory management, maintenance scheduling, and compliance reporting.

- Battery-Powered vs. Passive Tags: While many RFID gas cylinder tags are passive (powered by the RFID reader’s signal), some applications may require battery-powered tags. Customization options include the choice of battery-powered tags for situations where active communication or extended read ranges are necessary.

- Data Encryption: Enhanced security measures, such as data encryption, can be integrated into custom RFID gas cylinder tags, ensuring that sensitive information remains confidential and protected from unauthorized access.

- Scalability: Custom tags can be designed with scalability in mind. Businesses can start with a small-scale RFID system and expand it as their needs grow. Customization allows for easy integration of additional tags and readers as the operation expands.

- Regulatory Compliance: Different industries are subject to various regulations regarding gas cylinder management. Custom RFID tags can be tailored to meet specific compliance requirements, including record-keeping, inspection schedules, and reporting.

- Cost-Efficiency: Customization doesn’t necessarily mean higher costs. Businesses can work with RFID solution providers to design cost-effective, customized solutions that align with their budget constraints.

As we continue our exploration of custom RFID gas cylinder tags and their adaptability to diverse industries and applications, it’s essential to emphasize the long-term benefits and considerations that come with customization:

- Predictive Maintenance: Custom RFID tags can be programmed to collect data on gas cylinder usage and wear and tear over time. By analyzing this data, businesses can implement predictive maintenance strategies, ensuring that cylinders are replaced or serviced before they fail, thus reducing downtime and preventing accidents.

- Environmental Monitoring: In industries where gas emissions or leaks are a concern, custom RFID tags can include environmental sensors that monitor gas levels and air quality. This real-time data can trigger alerts and automated responses to mitigate environmental risks.

- Remote Monitoring: Custom RFID gas cylinder tags can be designed to support remote monitoring capabilities. This is particularly valuable in industries where gas cylinders are distributed across large geographic areas. Remote monitoring ensures that cylinders are tracked and managed efficiently, regardless of their location.

- User Authentication: In applications where safety and access control are paramount, RFID tags can include user authentication features. These features ensure that only authorized personnel can access and use gas cylinders, reducing the risk of accidents or misuse.

- Inventory Optimization: Custom RFID tags enable businesses to optimize their gas cylinder inventory. By monitoring usage patterns and reordering cylinders as needed, organizations can reduce excess inventory and associated carrying costs.

- Real-time Alerts: RFID tags can be customized to provide real-time alerts for specific events or conditions. For example, if a gas cylinder exceeds a certain temperature threshold or is due for an inspection, the tag can trigger an alert, allowing for proactive action.

- Audit Trail: Custom RFID gas cylinder tags can maintain a comprehensive audit trail of all transactions and movements. This audit trail is invaluable for regulatory compliance, internal audits, and dispute resolution.

- Data Analytics: The data collected by custom RFID tags can be harnessed for data analytics. This allows businesses to gain insights into their gas cylinder management processes, identify areas for improvement, and make data-driven decisions.

Conclusion

In conclusion, custom RFID gas cylinder tags represent a dynamic and responsive approach to gas cylinder management across diverse industries. The ability to adapt and tailor these tags to specific needs not only streamlines operations but also enhances safety, efficiency, and data accuracy. As businesses continue to recognize the value of RFID technology in gas cylinder management, customization remains a crucial element in harnessing its full potential.

Custom RFID gas cylinder tags are not just a technological innovation; they are a strategic tool that empowers businesses to optimize their processes, reduce costs, and maintain the highest standards of safety and compliance. In an ever-evolving industrial landscape, customization ensures that RFID gas cylinder tags remain at the forefront of efficient and effective gas cylinder management.